Product List

Safety and Monitoring of Zipper Machinery

2016-03-24

The safety device is used for protecting people and machine. The monitoring system is used to monitor oil temperature, metal temperature of injection molding machine, over capacity and equipment fault. It will indicate or alarm to handle all kinds of exceptional situations. Zipper equipment composes of safety gate, hydraulic valve, limit switch and detecting element, which achieve interlock protection of electric – machinery – hydraulic.

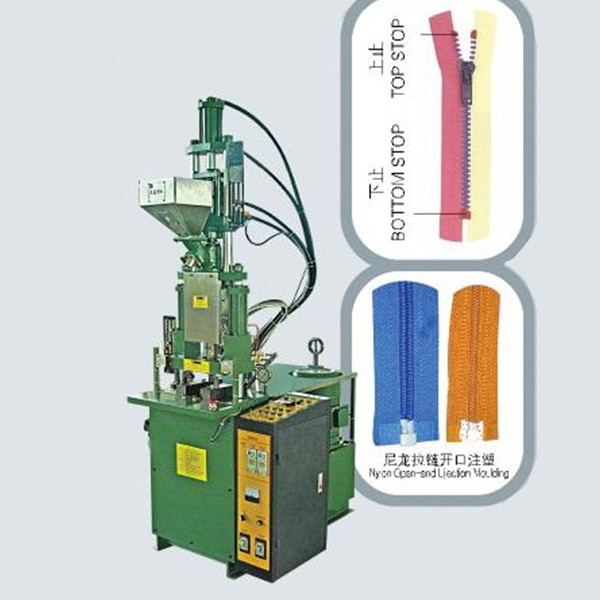

With the aid of screw thrust force, the equipment injects the plasticizing molten condition plastic into the closing cavity, and then removes the product through solidifying and shaping.

Injection molding is a cyclic process, each period includes: type quantifying feed - melt plasticization - pressure injection – mold filling, cooling – mold opening, pull-piece. Mold closing after pulling out plastic part and then process next circulation.

Semi-auto Double Pins Setting Machine (TYM-217M)

Semi-auto Double Pins Setting Machine (TYM-217M) Plastic Close-end Zipper Machinery (Auto Line)

Plastic Close-end Zipper Machinery (Auto Line) Semi-auto Hit Side Pin Setting Machine (TYM-226M)

Semi-auto Hit Side Pin Setting Machine (TYM-226M) Nylon Open-end Zipper Machinery (Auto Line)

Nylon Open-end Zipper Machinery (Auto Line) Auto Gapping & Punching Machine (TYM-201A2)

Auto Gapping & Punching Machine (TYM-201A2) Auto Bottom Stop Machine (TYM-216M)

Auto Bottom Stop Machine (TYM-216M) Semi-auto Box Setting Machine (TYM-204M2)

Semi-auto Box Setting Machine (TYM-204M2) Auto Plastic Zipper Gapping Machine (TYM-210D)

Auto Plastic Zipper Gapping Machine (TYM-210D) Auto H Bottom Stop Machine (TYM-223M)

Auto H Bottom Stop Machine (TYM-223M) Auto Open-end Zipper Injection Molding Machine (TYM-228A)

Auto Open-end Zipper Injection Molding Machine (TYM-228A)

English

English Russian

Russian Spanish

Spanish