Product List

Zipper Tape Ironing Machine

-

Nylon Open-end Zipper Machinery (Auto Line)

Nylon Open-end Zipper Machinery (Auto Line)

-

Auto Gapping and Punching Machine (TYM-201A2)

Auto Gapping and Punching Machine (TYM-201A2)

-

Auto Open-end Punching Machine (TYM-209N)

Auto Open-end Punching Machine (TYM-209N)

-

Auto Pin and Box Fixing Machine (TYM-203N)

Auto Pin and Box Fixing Machine (TYM-203N)

-

Auto Slider Mounting Machine (TYM-224N)

Auto Slider Mounting Machine (TYM-224N)

-

Auto Single Side Slider Mounting Machine (TYM-224S)

Auto Single Side Slider Mounting Machine (TYM-224S)

-

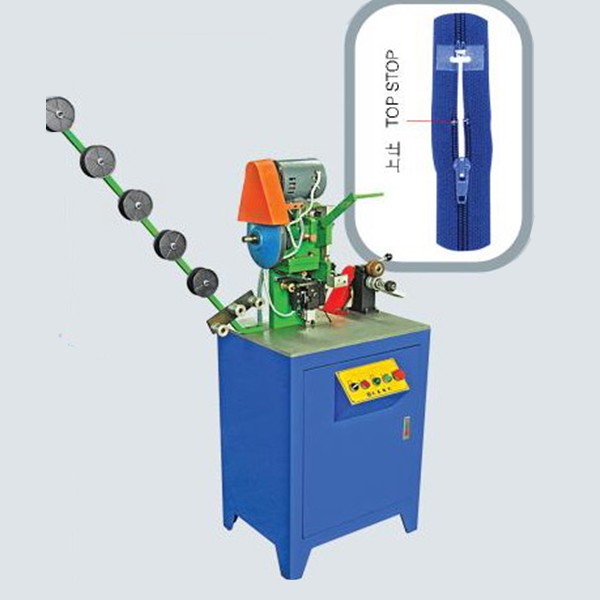

Auto Double Top Stop Machine (TYM-215N)

Auto Double Top Stop Machine (TYM-215N)

-

Auto Ultrasonic Double U Top Stop Machine (TYM-231)

Auto Ultrasonic Double U Top Stop Machine (TYM-231)

-

Auto Open-end Cutting Machine (TYM-220N)

Auto Open-end Cutting Machine (TYM-220N)

-

Nylon Open-end/Two Way Hit Backside Zipper Machinery (Semi-auto Line)

Nylon Open-end/Two Way Hit Backside Zipper Machinery (Semi-auto Line)

Description

This zipper tape ironing machine is used to finalize various types of the metal, nylon, delrin zippers' tape. It overcomes the drawback of no inner radian of traditional machine and reaches above 4 times weaving speed. Therefore, it saves a lot for the cost and increases the working efficiency.

Features of Zipper Tape Ironing Equipment

1. with imported special steel products, the components enjoys high preciseness, high stability and high energy efficiency.

2. It overcomes the drawback of no inner radian of traditional machine and reaches above 4 times weaving speed. Therefore, it saves a lot for the cost and increases the working efficiency.

3. It can iron 4 strips tape. Each tape will be ironed for 4 times so that the tape can be soft and have good inner radian as well as good shaping.

4. The space between the two transmission wheels has increased, making the ironing period longer and leading a better effectiveness.

Advantages of Zipper Tape Ironing Machine

1. Good effectiveness of finalizing design.

2. Directly iron the delrin teeth and metal.

3. Straight products after ironing with inner radian.

4. High productivity of above 4000-6000Y/H.

5. High energy efficiency (If working 8 hours per day, this machine can save energy charge for above 50,000 kilowatt hour).

6. This machine is more suitable for those want to outward process for the ironing so that it can save cost and increase the products' quality.

Technical Specifications of Zipper Tape Ironing Machine

|

Model |

QLQ-TIWM |

|

Production Capacity |

4000-6000Y/H |

|

Average output |

4000-6000Y/H |

|

Power |

15KW |

|

Voltage |

380V |

|

Dimension (CM) |

3006 × 60 × 190 |

|

Specification |

3# to 8# |

English

English Russian

Russian Spanish

Spanish